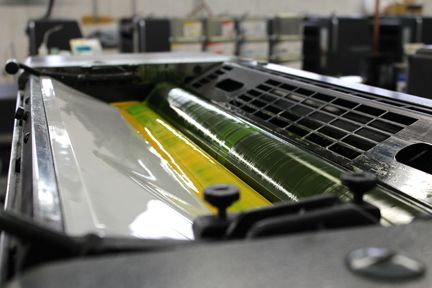

Edwards Printing Company has been in operation since 1979. Our business grew through our partnership with Heidelberg. We have been firm believers in their industry-leading presses and products from the beginning, and maintain an all-Heidelberg pressroom.

Our equipment is staffed and maintained by highly qualified technicians. Each member of our staff has at least 15 years of experience in the industry, many for decades. There have been monumental changes in the printing process over the last 45 years. From hot type to photo type, direct to film, direct to plate, and direct to press, we have lived the transitions and changes in the industry. We use that experience to produce the quality products that our customers have come to expect.

Here's what some of our staff have to say about our equipment and set up:

"I started in the industry as floor help, at the shop where my uncle worked. I liked learning a trade, and working my way through that shop was great job training.

I’m mechanically inclined and a hands-on learner. I like problem solving, figuring out how things work, and how to make them better. I enjoy working with offset printing because I like to think of it as an art form.

I’ve worked on all kinds of presses, but Heidelberg is the best. You could call me the Sultan of the Speedmaster. It’s the smoothest running, and produces the highest quality product- it’s just a superior machine.

We offer a more consistent job from start to finish, with much less waste." - Chris O'Brien, Press Operator

"I’ve worked with a lot of different presses, from Manroland to Komori, but I like Heidelberg most. It’s simply a high-quality machine. There’s less maintenance, it’s a high quality design, and you get the best result with cooperation between prepress and the pressroom.

In our industry, being able to minimize makeready time is huge. Proper collaboration between prepress and the pressroom results in less waste, highest efficiency, and a quicker project turnaround.

I love understanding every aspect of these machines. I know my press front to back, and there’s always room to learn more. The focus on collaboration, teamwork, and dedication to consistency is really important. We don’t mess with quality." -Dan Field, Press Operator

Pressroom

-

Heidelberg Speedmaster SM 74-5

- Five color with aqueous coating tower

- CPC controlled with Prepress Interface

- Autoplate

- Vario dampening

- Grafix drying system -

Heidelberg Speedmaster SM 74-4P

- Four color with aqueous coating tower

- 2 over 2 automatic switchover perfecting

- CP2000 controlled with Prepress Interface

- Autoplate

- Drystar drying system -

Heidelberg Printmaster

- Two color

- Autoplate -

Versafire Pro C7110X- Prinect DFE

- 5th Color or spot/flood clear coating -

X-Rite Spectro-Densitometer Controlled Pressroom

Bindery

-

Heidelberg Stitchmaster

- Three knife book trimmer

- 4 pocket plus cover feeder

- Casting unit

- Trimmed minimum book size 3.5" - 5.5"

- Trimmed maximum book size 12" - 13.75" -

Polar 115 Monitor Programmable Cutting System

- Jogger

- Paper Scale

- Lift Table -

MBO 23 x 36 Continuous Feed Folder

- 8 and 16 rollaway units

-

MBO 20 x 26 Continuous Feed Folder

- 8 page rollaway unit

- Inline Slautterback fugitive gluing system

Prepress

-

Heidelberg Printect Prepress Interface

- Serves CIP4 data to pressroom for accurate ink zone presetting

-

Heidelberg Suprasetter A75 Gen III CIP Platesetter

- Prinect Workflow

- Chemical Free - Thermal -

Epson Stylus Pro 10600 Ultrachrome Large Format Proofer

- ICC color management

-

Epson SureColor P9000 Digital Proofer

- ICC color management

-

X-Rite Advanced Color Management Ensemble

- DTP70 Scanning X-Y Spectrophotometer

- DTP94 Colorimeter for LCD monitors

- Monaco Profiler Pro

- GregtagMacBeth Profile Maker -

Beta UltraDottie 2 CTP Halftone Analyzer

- Betatab data acquisition software

IT

-

EFI Pace Print MIS System

-

Corporate Mail Server

-

QNAP Network Attached Storage Devices

Online Print Inventory Management & Fulfillment Platform

- Custom user portals

- Real-time inventory tracking

- Automated reordering thresholds

- Reporting and usage analytics

Specialty, Fulfillment, Shipping and Delivery Operations

-

Bessler Shrink Packaging System

-

Variable Head Paper Drill

-

Acme Industrial Semi-Automatic Stitcher

-

Full Presort Mailing

-

Authorized FedEx, UPS, and DHL shipper

-

Delivery Fleet